Posted By: Robert Nickels (ranickels) Posted: 03/19/2022 Technical 03/19/2022 |

Ceramic Loading Capacitor Replacement32V series, Vikings, etc |

|

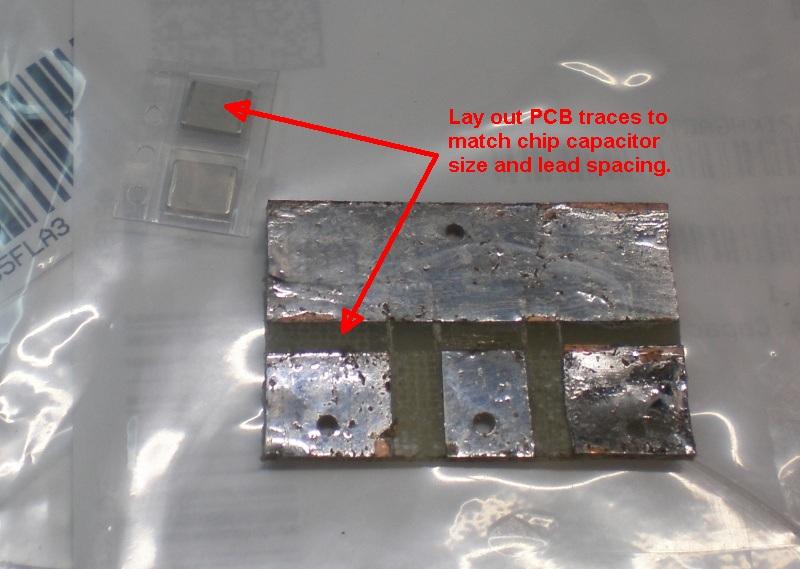

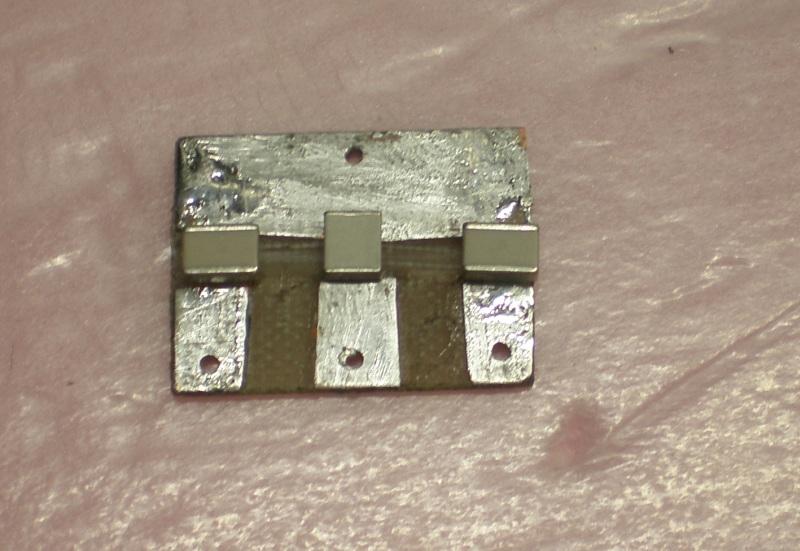

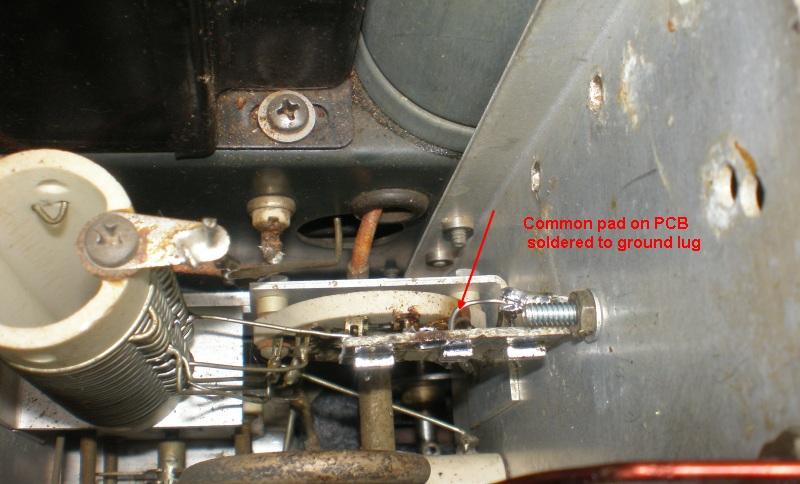

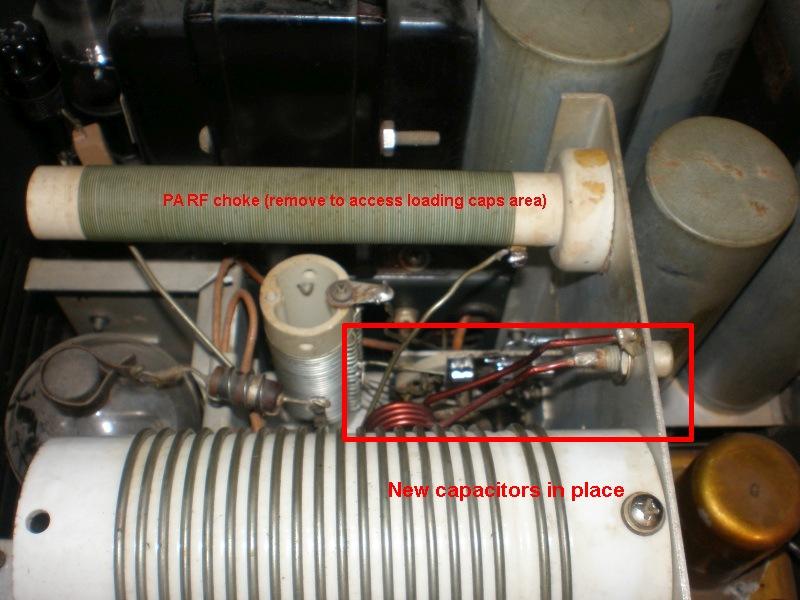

Old style mica capacitors were used in the pi-net matching sections of several vintage transmitters and the combination of age, heat, and high RF currents have made them likely failure items. My Collins 32V-2 transmitter was to the point where it would not properly load to full power on 75 meters so something had to be done. Mica capacitors are no longer made but fortunately new multilayer ceramic capacitors are and provide superior performance and specs. Before going into the replacement itself, take a few minutes to understand how modern automated manufacturing and testing processes have been applied to produce multilayer ceramic capacitors to such high standards: KEMET VIDEO One benefit of automated manufacturing is consistency - once a capable process has been developed, modern automated factories can reproduce the same result time after time, millions upon millions of times each year, with nearly zero defects. In contrast to the old mica capacitors that often fail due to variabilities that allow moisture entry, metal migration, and changes in dielectric strength to cause deterioration and failure. Multilayer ceramic capacitors are commonly available with voltage ratings that greatly exceed the original mica caps. I went with 3KV rated capacitors for a nice safety margin. While not all capacitance values are available, multiple capacitors could be connected in series or parallel if needed. Be sure to choose only C0G/NPO type capacitors! Here is a link to the 220pF 3KV capacitors I used: MOUSER LINK The biggest problem in the Collils 32V-2 is the limited access to the output circuitry but by removing the plate choke it can be done. The first step is to remove the three mica capacitors, Clip or unsolder the leads at the capacitors and leave them attached to the switch as they will be re-used. The size of the 3KV capacitors is about 1/4" square so the usual fear about hand soldering SMT devices doesn't apply. However it is not good practice to try to solder leads directly to the metallized ends of the parts; the photos show how to make a simple PC board that provides proper mounting and attachment. I needed 3 capacitors but the board can be made a big as needed. A small piece of copper-clad one-sided laminate is all that is required - readily availble from eBay sellers if necessary. The pad layout is drawn or marked off with masking tape directly on the copper, It's a matter of a few minutes work to scribe the required cuts with an Exacto knife and peel away the unwanted copper, leaving the pattern shown. Apply a bit of solder to one corner and the laminate will peel up easily. I then tinned the entire pad area with a thin coating of solder and drilled a small 1/16" dia. hole at the outer end of each of the three pads, and one along the common pad area. It's easy to hand-solder the caps in place. The existing wires are then bent around to align with these holes and soldered to the PCB. The wires are quite stiff and sufficient to hold the PCB in place. Finally, install a new wire from a ground lug to the common pad on the PCB. (Different radios may vary). Once the rework is done the PA RF choke can be put back in and checked-out. Improvements were made in the Collins 32V-3 to address the underlying conditions that contributed to early failure of the loading caps in the 32V-2. The 32V-1 was different yet, so it's clear that Collins was still trying to make up it's mind about how best to implement the loading control, but with an added safety margin AND by following Collins recommended tune-up procedure I haven't have any issues with the replacements.

|

|

Related Images

Click on the image title or on the image itself to open the full-sized image in a separate window.Latest Articles

|

Crystal Replacement

Posted: 02/38/2024

Comments: 0 |

How good can a crummy receiver be?

Hundreds of different simple SDR receivers have been designed around Dan Tayloe's Quadrature Sampling Detector or QSD. Mine add nothing to the state of the art, and in fact subtract things, as I like minimalist solutions and the QSD is right in that sweet spot. Following the evolution of Tayloe's design I delete the resistors in series with the sample lines for inst... READ MORE |

Technical

Posted: 02/37/2024

Comments: 0 |

What's in a number (3253)?

The FST3253 dual four-to-one mux/demux IC has long been used as a "Tayloe Detector" or QSD (and QSE) in low-cost SDRs. They provide incredible performance for such a simple circuit, converting RF to baseband IQ with low loss and the ultimate in simplicity. Unfortunately the original FST3253 part has become obsolete and while substitutes are available, this is where the... READ MORE |

Vintage Ham Radio

Posted: 02/32/2024

Comments: 0 |

The Stancor 10P Transmitter

There weren't really many commercial transmitters in the 1930s as most hams built their own. But many of the ones that were offered came from the transformer companies who had two chances to profit. First, from those who would buy the kit, and two, from those would would see it in the (free) booklets the companies provided to their distributors who would then sell the iron to ham... READ MORE |

Vintage Ham Radio

Posted: 12/355/2023

Comments: 0 |

The Care and Feeding of the EF Johnson Courier amplifier

The EF Johnson "Courier" is a grid-driven amplifier using two 811A tubes. Switching is provided for operating in either class C for CW or as a class B linear amplifier for AM or SSB. Rated power is 500 watts input for CW, 500 watts PEP input for SSB, and 200 watts input for double-sideband AM with carrier. Since all amateur power levels were meas... READ MORE |

Historic

Posted: 11/329/2023

Comments: 0 |

TV Duplexer

Some things are interesting, even if totally useless nowadays. Such is the case with the Philco 426-3034 Crossover Kit for UHF TV. What the heck is that? Well, back in the late 50s, UHF television stations operating on channels 14-83 started to appear in many areas of the US where viewers had a VHF-only TV antenna, and in many cases an externa UHF converter was... READ MORE |

Crystal Replacement

Posted: 11/327/2023

Comments: 0 |

Replacing failed crystals

For decades, quartz crystals were used everywhere a stable frequency source was needed, even in some applications that depended on overtone (harmonic) behavior into the VHF range. These crystals were less stable and more dependent on circuit parameters that fundamental types and thus more problematic. Such was the case with the 94 MHz crystal in the 2 meter converter ... READ MORE |

Historic

Posted: 11/315/2023

Comments: 0 |

My Own Ham Radio Story by W9RAN

Everyone has a story of how they got involved in ham radio - this is mine. It started much earlier, including receiving a Knight Kit Span Master shortwave radio for Christmas in about 1963, at age 12. I'll never forget the night my dad and I finished building it and I wanted to try it out. It came with a 50 ft. antenna which was still coiled up - but ... READ MORE |

Technical

Posted: 09/267/2023

Comments: 0 |

Hot to simulate vacuum tubes in LTSpice

LTSice is a powerful simulation tool that is provided free by Linear Technology Corp. It comes with a complete library of passive and common analog solid-state components but if you want to use it to simulate vacuum tubes, it doesen't work as-is. Even though triode and pentode symbols can be found in the "Misc" folder, they are just schematic symbols and... READ MORE |

Friends Remembered

Posted: 07/208/2023

Comments: 0 |

Merv Schweigert, K9FD (SK)

Comments from Robert Nickels W9RAN, July 27, 2023: There is nothing worse for a ham radio operator than to see a beloved friends callsign with the letters "SK" behind them. Yet sadly, that's what happened on July 23, 2023, when I learned of the passsing of Merv Schweigert, K9FD. While many of our ham radio interests were different - Me... READ MORE |

Vintage Ham Radio

Posted: 01/19/2023

Comments: 0 |

"Winter Projects"

I know many of us who enjoy restoring and repairing vintage gear look forward to winter when there is less competition for time and energy, and a chance to really make a dent in our "to be fixed" piles. A couple of years ago I set time aside for "Heathkit Singlebander Week" and went through every one of them I had, with the result that they're all working ... READ MORE |