The following information is attributed to Jim Liles, K9AXN. Jim a long time user and expert on the Hallicrafters SR-2000 "Hurricane" with involvement going back to it's original production. His website www.k9axn.com contains a lot of valuable information and is recommended.

RCA developed the 8122 which was also built by Burle, and later, Eimac (as you will read below). Refer to the datasheet in the "Attachments" section at the bottom of this page for full details about the tube.

One topic he focuses on is the 8122 power tetrode used in the SR-2000 PA as it is the source of the Hurricane's desktop kilowatt power - and a great deal of frustration for users. This explains the "inside story" of the 8122 and why it requires special care in tuning:

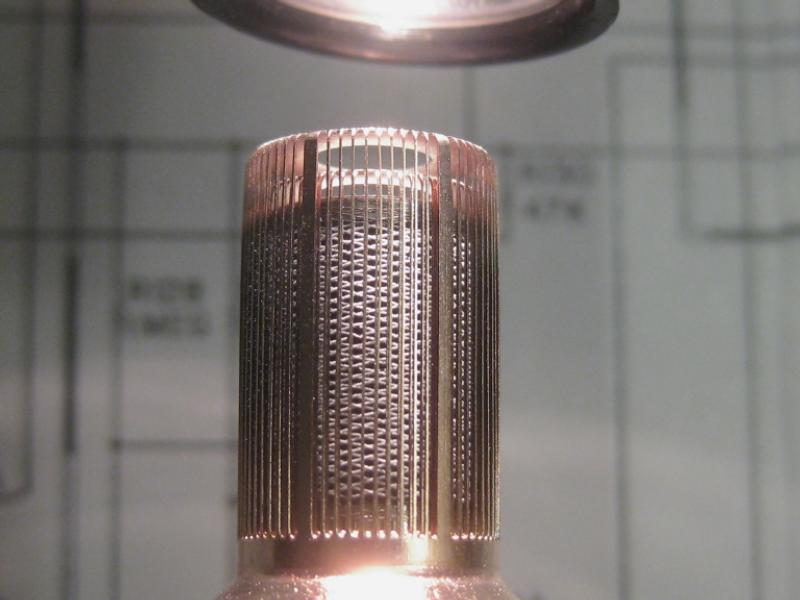

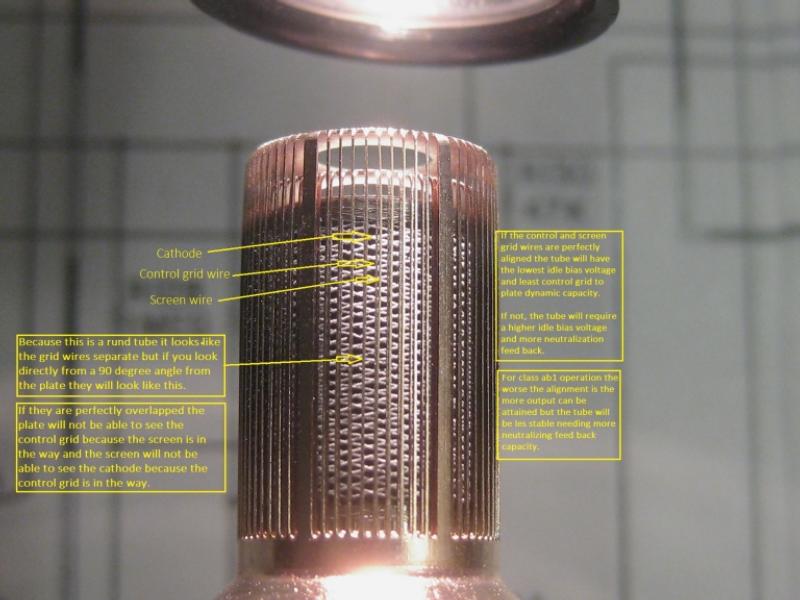

The following photos are of a standard 8122 and a 4662 which is a ruggedest 8122.

Note, the only obvious difference is the cathode in the 4662 is a flat surface and the 8122 is a wire matrix. The Barium and Strontium oxides applied to the cathode are delicate and can be dislodged with vibration. The filament in both is approximately half the diameter of the cathode and not visible. NOTE: If you should decide to dissect any tube using an oxide coated filament, beware the Barium oxide is incredibly caustic. You don't want to get the dust on your skin or breathe it.

The first photo is an 8122 and visible are the cathode (wire matrix with the screen and control grids overlapping each other.

The second photo represents the cathode, control and screen grids. Expand it to view the wording and pointers.

The third photo is the 4662. Note the solid cathode and the precision alignment of the CG and SG wires.

The alignment of the CG and SG wires hide the CG from the plate and the SG from the cathode. The result is the dynamic CG to plate capacity is significantly reduced and the screen current is reduced.

This explanation of the RCA 8122 sets the stage for the following comments about the 8122 at the worlds leading power tube company, Eimac, courtesy of former Eimac engineer Reid Brandon W6MTF, who posted his recollections on QRZ.com. I think you will agree his recounting of these events explains some of the reasons for the fragility of the RCA/Burle design and why Eimac was the industry leader, even if not on the 8122 product line.

Or how "Form Fit and Function" are impossible to meet 100% unless a DIRECT COPY is done.

The 8122 is a small metal-ceramic tetrode which was developed by RCA in the early 1960’s. The 8122 is a high transconductance tube that was intended for use in communications equipment for HF radio and a version of this tube is used in distributed amplifiers for EMI testing.

In his Final Report TR69-1, “Zero Bias Triodes Segmented Oxide Cathodes”, by William H. Sain of Eimac (at the time a division of Varian), mention was made of using the 8122 as a basis for his prototype work on a new type of tube. The goal was to make a triode that would perform as well as a tetrode. This was to be accomplished by using a segmented cathode that would form axial beams of electrons and the concept was later called the focus-cathode triode and one end product was the 8877, designed from start to finish by Bill Sain in only 10 months.

Eimac had attempted to get into the business of competing with RCA for 8122 business in the 1970’s. At some time in the 1980’s RCA sold the Lancaster, PA tube plant and it became Burle Industries, the name adopted by the new CEO, Dr. Erich Burlefinger. By the early 1990’s the 8122 was selling into the replacement market in quantities of approx. 2000 pieces per year at a unit price of approx. $160. For purposes of comparison, the 4CX250B was selling for approx. $85 at that time so it should be obvious that there were profits to be made.

It is important to note that because the 8122 had an 11 pin base, it was chosen as the basis for what led to the development of the Eimac 8874/3CX400A7 focus-cathode triode. Prior to this time no Eimac tubes used the 11 pin base. Another thing worth mentioning is the cathode in the 8660/4CX1500B tetrode was used as the basis for the 8877/3CX1500A7 development program because it used a focus cathode which looked easy to transplant into a triode. Ultimately, several focus cathode triodes that resulted from this effort have become immensely successful commercial products and are still in widespread use in Industrial (laser) and communications equipment and other interesting applications, including the YC-156 and the YC-179 in medical equipment (MRI).

When Eimac set out to compete with RCA on the 8122, it was discovered that RCA’s grids were made using a technique not employed by Eimac. RCA used an electro-discharge machine (EDM) process with the trade name “Elox” that literally burns long slits (openings for passing electrons) into hollow cylinders made from molybdenum in a continuous, albeit slow, process. Another approach was using thin sheets of moly that could be etched using an electrochemical process and later rolled into a cylinder and spot-welded along the seam. The latter method was similar to making printed circuit boards and would have been more of a mass-manufacturing approach except the grids made this way tended to change shape when hot; grids made using that technique were tried by Eimac on the 4CX600J with mixed results so it was decided to not use that scheme on the 8122. Both of these methods are quite different from the conventional Eimac technique of making grids where thin bars of moly wire are inserted into grooves on a precision mandrel then a spiral tie wire is wrapped around the circumference to hold the bars parallel and spot welded by hand (well, by foot actually, the welding machine is pedal actuated). It was decided to adapt the Eimac style of grids for manufacturing a tetrode that would work in the 8122 application.

The idea of making Eimac 8122’s came alive in 1983-84 when the US Government came out with a large purchase RFQ for the URT-23 radio transmitter system. The URT-23 consists of an rf amplifier type AM-3924 which uses two 8122’s in parallel driving two 8660/4CX1500B tetrodes and has been built by companies including Radio Frequency (now part of Harris Corp.), Stewart Warner and Target Corp (not to be confused with the consumer stores of that name). This is a shipboard radio that is still in use.

Eimac’s marketing dept., headed by George Badger, W6TC, decided to enter the 8122 market and to compete in this new opportunity. Heroic efforts do not always come to fruition however and the story of the 8122 can now be told.

In the early 1980’s Eimac had hired several of RCA’s tube engineers. The engineering manager at Eimac at that time, Tom Yingst, was one of those individuals but the Eimac engineer in charge of the 8122 project, Bob Tornoe, decided to use grids made on mandrels, the same technique that was developed at Eimac for the 4X150A in 1947 and later, around 1961, this tube became the 4CX250B and was still being built in large quantities at Eimac in the 1980’s so it should be obvious that this was a tried-and-proven manufacturing method because after almost 40 years of use, the technique was well established at Eimac. One could also surmise the firm was pretty well "set in its ways".

A program was established then to make a tube that would work as well as the RCA 8122, meeting its specifications of form, fit and function using wire grids.

Now, to physically align and mount the Eimac grids in the 8122 with its 11-pin header required a different technique than what was used in Eimac’s small tubes so small insulators were placed over certain pins using tweezers and the grids were mounted afterwards to the pins on the header. This procedure turned out to be much more labor intensive than Eimac’s original 4CX250B style of manufacturing and at the same time the accounting system was changed from a corporate directive so the costs captured showed poor profits. Nonetheless Eimac was able to get a few orders for 8122.s.

Then a report came in complaining that Eimac 8122’s were oscillating in the URT-23 amplifier. Bill Orr asked me to accompany him to a U.S. Navy site where equipment was made available for us to evaluate the issues. Carrying a new set of tubes, Bill and I went to see what the problem was and discovered that in fact Eimac 8122’s were oscillating while Burle/RCA 8122’s were stable. A close look at the socket showed the screen bypass capacitors (a couple of ceramic disc capacitors) had fairly long leads, not a good thing for an effective bypass capacitor. We suggested these be made as short as possible and after a quick modification to remove approx. one quarter of an inch of lead from each capacitor, the equipment performed properly without oscillating. With this information I went off to visit the prime contractor to show them our solution. Unfortunately they already had a contract to buy 8122’s from Burle and they were not inclined to do anything whatsoever to their construction methods and besides that, they already had delivered large numbers of amplifiers with capacitors having long leads. The reason Burle tubes did not oscillate is because of different internal construction. The interelectrode capacitances were different between the RCA design and Eimac’s tubes and it would have been a huge task to recall thousands of transmitters to perform a field retrofit to shorten the cap leads.

Eimac then set about to develop a modification to the tube, by altering the capacitance to so it would be similar to that of the Burle tube. By making the small ceramic insulators larger and placing metallization on them in the appropriate places a prototype was built that had the right capacitance as the Burle 8122 but it was too late, the labor involved to build this new version of the 8122 was considerably more than initially calculated and accounting people caught up with internal costs and even if the market was one with “open arms” the fact is it was impossible to compete with the Burle’s well-established manufacturing capability.

Tubes made with Eimac’s grids were superior electrically, they had more gain that the RCA design. Electrical performance did not vary much from one Eimac tube to another and this would have been welcome to users who needed replacement tubes in the field because RCA (and later Burle) tubes had to be matched closely in order to meet equipment performance requirements. The Elox or EDM technique left some variation in the slot widths so electrically their tubes were not as uniform as Eimac tubes.

The URT-23 had no means for electrically balancing the two 8122’s so that made it necessary to use closely matched tubes. For this reason Burle used color dots applied to their tubes to indicate a range of electrical characteristics. If two Burle tubes with different color dots were used the amplifiers possibly would not perform to specifications. Because of the excellent uniformity attributed to the mandrel-made grids, Eimac tubes could be chosen at random, installed into the URT-23 and the equipment would have met the test requirements but this was never to come. The 8122 program was scrapped as a failure.

Somewhere along the way, Eimac purchased a National NCL1000 linear amplifier to use as a test vehicle in the lab for evaluating 8122’s. Later it was used as a driver for a 4CX15,000A in a Rockwell Collins transmitter after the Collins driver circuits failed to auto-tune properly.

The above is one of my Eimac stories I present at times on qrz.com

73, Reid Brandon W6MTF

Of course companies enter a market because they perceive there is money to be made, and Eimac's decision to start making 8122s is no exception. In the following stories Reid Brandon explains what motivated Eimac to do so and some of the issues that affected their success.

The problem with the 8122 as you go up in freq the type of socket used begins to be of inportance with respect to circuit stability. Some Erie sockets made for these tubes had built in screen bypass caps (and were gold plated - I still have some and they should make nice paper weights!). The cheap plastic 11 pin sockets did not have integral bypassing so disc ceramics were used and their inherent parasitic (>!) inductance caused the URT-23 transmitterrs (exciters) to show instability with Eimac tubes but they were stable with Burle tubes, as discussed in my little history on the 8122. If I hadn't been there and witnessed the issue with Bill Orr I would probably have doubted such a story.

>! BTW I hesitated to use the term "parasitic" because old wounds never heal - you never know when some obsessive Troll might get his juices worked up on such a word, ha!

A "W" suffix in the type number indicates a ruggedized structure but the electrical performance should not differ.

On that note, RCA (later Burle) made a 4657 which was a ruggedized 8072 because it had to operate in mobile radio transmitters and the 8072 grids would move if the tube received shock or vibration as expected in a mobile rig, so they added something mechanical to keep the grids stable.

When Eimac made a few 4657 on order the tubes were simply 8072's labelled 4657 since nothing was necessary to add stability to an already stable structure.

I always wondered why the EIA designations in this family of tetrodes are so far apart? Like the 8121, 8122, etc. all have the same basic internal structure then you have the 4657 8072 same basic tubes but without air cooling fins. Note the wild range in EIA type numbers. BTW the EIA used to supply historical data sheets from their Washington DC location on Eye Street (its funny how I remember little things like that!) - I wonder if they are still operating?

I'm sure some savvy ex-Burle or RCA employee would know.

cheers,

Reid W6MTF

Hi Jim, Eimac didn't often provide range values for bias voltage if thats what you mean. Range values for capacitance, yes, those are generally available and used at QA to track the proper alignment because if physical respects internal to the tube are "off" very much a tube may still perform electrically in terms of delivering plate current and so on but the capacitance will start to wander and that trend may alert you to something that will affect customers using the tube esp at higher freqs with respect to tuning. Also the normal tetrode data sheet (such as provided below) states a specific grid bias in class AB1 to obtain a specified plate current. That bias varies quite a bit with ANY tube and is why circuits with really demanding (ie. Mil) specs for IMD for example will have balancing pots for bias or require using a matched pair. That takes us back to URT-23 and the color dots on Burle tubes.

During the second 8122 manufacturing period (the first was around 1970 and eventually production was stopped for some reason -(I wasn't there so I don't know the details) I was asked to work on a new data sheet.

I remember discussing the possibility that some Eimac customers might raise issues over the Burle tubes having color dots and Eimac tubes didn't. The devils advocate said a possibility existed that when military users went to replace tubes and, following the tech manuals as they always do, they looked at Eimac tubes with no color dots they would halt the work and end-up returning the tubes as deficient, ie. lacking color dots. We considered using the same color and putting dots on the tube regardless but Eimac never got the big order for thousands of tubes from Stewart Warner, something that I discussed before (and neglected to mention the prime contractor) so it was a moot point.

Incidentally some Burle tubes had a color painteed to the small top on the tubulation cover while most tubes we saw (ahem, bought for verification putposes) had 2 small dots, either black, red or blue and I don't know how exactly how many variations of dots they used.

You think thats an odd story?

Well, I have another anecdote that is similar and may seem even more ridiculous.

Eimac was delivering tubes to Continental Electronics for an OTH radar, the one that tracked - who was pres in '84? - Reagan or was it the first Bush? I think it was George Bush Sr. who flew to Iceland, anyhow the radar worked, even though it only a small version of the Russian Woodpecker.

The radar used a water cooled 25kW tetrode as a driver and a 50 kW tetrode in the PA. The anode of the tube had two water pipes coming out the top and it didn't matter which pipe was used for in or out, due to the internal symmetry. The tube was mounted upside down and the fear was that a air bubble might form and prevent proper cooling, a valid concern but it just wasn't an issue as far as Eimac was concerned.

But the US Navy or USAF or whoever took responsibility of operating and maintaining the radar came running to Continental asking which pipe was "in" and which was "out". My explanation that it didn't matter fell on rigid miltary ears, so Continental asked me to have the tubes labelled IN and OUT just to satisfy some mil guy in a uniform who wanted to enable his men to do something without getting confused. The Radar system used the East coast and the West coast for isolation, no T/R switch required!

So I had to reprint data sheets accordingly and we changed work instruction sheets to be consistent with ISO documentation requirements (my opinion of ISO is prety low and not worth going into here!).

Ironically the FPS-118 radar was mothballed only few years after its implementation, probably because of high operating costs. Parts of it were sold or scrapped. A US Senator proposed to congress keeping it alive or I believe proposed some other use I don't know all the details but that just goes to show another way our Taxpayer Dollars get wasted!

To this day the tubes are still labelled IN and OUT but I'll wager no one save the folks that read my story here will know why!

In retrospect, I think the entire radar was a good idea until you consider that Satellites can do that better and now there are drones etc.

cheers!

Reid W6MTF

8122 family data sheet attached

Glad you enjoyed it. Here's another one

As we approach Independence Day 2017 let us remember when America came dangerously close to being a subject of the USSR, during the Cuban Missle in October 1962. President John F Kennedy carefully, in non-negociable terms (except for what was supposed to be a secret agreement for the US to remove its missles from Turkey) created a better world for both nations.

The Cuba missle incident led to the U.S. building the FPS-85 radar to maintain vigil on the area South of Florida in case such a thing might be attempted a second time. The radar has operated continuously, except for minor maintenance and a fire I describe below, and today it is an important asset for watching space debris.

If Eimac had been unable to supply a couple of special tubes in the past few years, the radar would have either been shut down or it would have to be converted to solid state, either of those paths would have been a lot of down time and that just wasn't in the cards.

Eimac comes to the aid of an aging military radar – twice!

There is an interesting story behind tubes used in the FPS-85 radar at Eglin AFB in Florida. Not one, but three tubes that Eimac makes are necessary to keep the radar there operating.

This is a well-known radar system; it was built during the 60’s and was intended to be a significant tool to be used as a threat deterrent after the US discovered Russian missiles on the island of Cuba. Today it serves the important function of tracking space debris, stuff left in orbit after the launch of a satellite or other rocket and it is one of several sites dedicated to that purpose.

The FPS-85 is a phased-array radar and it was built around a large wood structure that holds the array of antennas with an rf amplifier at each antenna.

Unfortunately, the structure caught fire shortly after it was completed and it burned to the ground because there were no means of putting out the fire. Perhaps the fabric cover that encompasses the entire array caught on fire, after all high voltage is routed across the entire antenna and either that or a lightning strike from the frequent electrical storms that occur at the South end of the Floridian peninsula may have been responsible.

There is a beautiful fire house located on the site now, located near the entrance to the radar, the side away from the antenna array. I imagine a story about life as a fireman there would not be very interesting as hardly any tourists even venture this far South besides the armed guards at the entrance make it less than a friendly vacation spot.

The electronic system at Eglin consists of a pulser downstairs feeding pulses of current at high voltage to the array of 5184 individual UHF amplifier modules placed across the face of the array, each antenna is fed by an Eimac 4CPX250K and the rf radiated energy is combined in space.

The specs for 4CPX250K are quite impressive for a tube of its small size (2.8 inches long and weighing only 4 ounces). Tubes are tested at Eimac and must deliver to the load a minimum output of 10 kW at 442MHz for 250 microsecond pulses at 0.005 duty. At an NAB show one year I met an individual who was involved with a special series of tests on samples provided for consideration when the radar was in a development phase. Basically, he said both RCA and Eimac tubes had been submitted (to Bendix?) for evaluation to determine which would ultimately be used in the rf modules for the FPS-85. I believe he indicated the first radar at the site used a GE triode that was designed into the radar but couldn’t deliver the power necessary to meet performance objectives.

It was said that RCA tubes sparked during the peak power test. I learned that Eimac had considered this so they had processed the samples using a special high voltage processing called de-barnacling in the industry, this allowed 4CPX250K’s to reliably hold-off over 5000Vdc. Ultimately Eimac was awarded a contract for thousands of 4CPX250K and many more have been delivered over the decades the radar has been in operation.

Now, enter the Westinghouse WX-4778. This is a unique tube having a small oxide cathode triode with a Mu (amplification factor) of 20. It is also designated 5960-00-892-9475 and this tube is truly “extinct”. Westinghouse made glass special purpose and receiving tubes at their Red Bank, NJ factory and the WX-4778 may have been made at that facility. I believe the WX-4778 is the highest power tube having an external anode with an oxide cathode that Westinghouse ever made. It uses a small glass bulb below the anode and the base appears unique with two pins extended for supplying heater power. In the samples I have seen the base is made from fused glass, a material Eimac used in early 4X250 tetrodes and discontinued after it was found to be susceptible to vacuum leaks.

The grid flange on the WX-4778 is part of a cup that terminates in the glass base insulator and there is a heliarc weld around the relatively thick rim which constitutes the grid terminal.

The anode cooling fins on the WX-4778 have a series of dimples to increase air turbulence, a simple technique but not as effective as the louvers on Eimac air-cooled tubes which provide increased cooling efficiency. The rated dissipation for the WX-4778 as indicated on the Westinghouse data sheet is 600 Watts which is pretty impressive considering the fact its anode isn’t much larger than that on a 4CX250B! Westinghouse states this dissipation requires air flow at 30 CFM with a modest pressure drop of 0.5 in water.

Looking at the overall system one sees there are 16 banks of pulse modulators for the over 5000 4CPX250K’s. The first tube in each pulse modulator is a type 5687, a low power glass dual triode (think audio!) which drives the WX-4778 and that drives four 4PR60C tetrodes in parallel, these tubes remove bias momentarily from the final tube in the chain, a big F8147A triode which drives a pulse forming network and that then supplies pulsed plate current to groups of 4CPX250K’s. The total combined rf output from the array is 32MW peak. The F-8147A was designed by ITT in the 1960’s and is a whopper, weighing in at 22lbs, it has a 7.5kV max anode rating and can deliver up to 150 amperes peak current but to do that requires the grid be pulsed up to approx. 2000v.

Now, the first “Bail-Out”: Suddenly, at some point around 1999, Eglin’s stock of spare tubes was nearly exhausted and ITT had been sold to Triton Services which had deteriorated to the point it could no longer supply good working tubes (in 2008 Triton would declared bankruptcy and close its doors) so a government contractor responsible for maintain the radar asked Eimac if it could make an equivalent to the F8147A. Having nothing similar, Eimac developed the EI8147A (5960-00-720-0615) and CPI continues to supply that tube for the FPS-85, the only system that uses it.

Then, an opportunity for a second “Bail Out” occurred: In 2007 the USAF asked Eimac if it could supply an equivalent to the WX-4778. The situation was getting urgent because they had almost depleted their stock of spares of this unique tube. As is normal practice for government systems, they had purchased a large number of WX-4778 and warehoused the tubes. Subsequently Westinghouse discontinued that tube when it went out of business in the late 1960’s or early 70’s. Fortunately the operating life of the WX-4778 was good so the use-rate was fairly low, nonetheless they suddenly found themselves with almost no spares and another crisis was at hand!

I was asked to recommend something so I compared the constant current curves of all the triodes Eimac made in 2007 to those of the WX-4778 and I was able to find one tube that had very similar curves: the 3CX1000A3. Although this was a tube with thoriated tungsten filaments and was quite a bit larger than the WX-4778, theoretically it appeared it should work with little or no other changes. The filament transformer was different and there were a few mechanical details associated with the socket. Chris at Universal Transformers in Farmersville, TX supplied a custom filament transformer and delivered it to the contractor at Eglin and, when everything was installed in place of a WX-4778 the radar worked perfectly and it has now been retrofitted to use Eimac tubes in both critical sockets thus CPI successfully rescued the FPS-85 radar twice!

|